|

All you need is a carboy cap which is typically a yellow or orange rubber cap with two posts (usually with two little rubber caps on it) and some sort of hose connected to your carbon dioxide tank. The carboy caps are sized for different size carboys so keep that in mind when you are buying one.

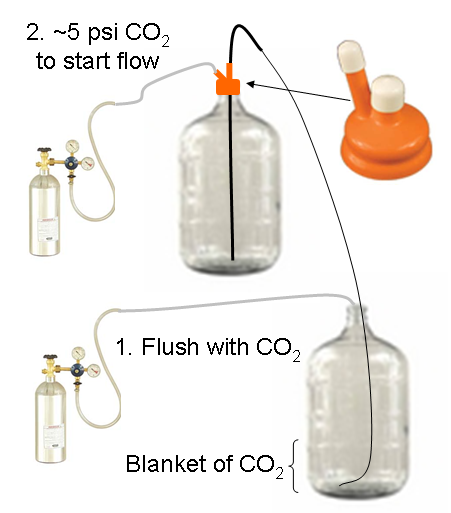

First, you take your racking cane and carefully push it through the center post of the carboy cap (see the diagram). Sterilize this arrangement as your hosing. Meanwhile, you can flush your carbon dioxide or other transfer gas into your sterilized receiving carboy or bucket. Personally, I either blast in for about 10 seconds or flow it in slowly for up to a minute. If someone has well-documented numbers, let me know! Give it a few minutes to allow the gas to settle into a blanket on the bottom.

Next, attach your carboy hood with the racking cane to the carboy. Get your racking cane down to a suitable level under the surface and attach your hose to the cane and gently put the other end down at the bottom of the carboy.

Now, get your carbon dioxide setup and get it close to the full carboy. If you have a screw off fitting for your air attachments for your keg, the fitting with the screw-on attachment works great (both for flooding and applying pressure to the carboy cap). Just unscrew the gas fitting so you have an "open" hose. Turn on your carbon dioxide to approximately 5 psi. All you have to do is press it against the other "post" on the carboy cap and within a few seconds the siphon should start. Once it starts you can remove turn off your carbon dioxide. Technically speaking, you could keep flowing it on top; however, lets face it, carboys aren't necessarily designed as pressure vessels so trying to minimize the pressure exerted on the carboy is probably good.

Sometimes you may have problems with little leaks in which case you may need to increase the pressure a little or find a way to temporarily block the leaks. Also, it is possible to do this with barrels and buckets if you are creative, but it is not as easy (lots of gas leaks and bucket tops may pop off).

This really makes racking a breeze and lowers your chance of oxidizing during transfer (for wine folks, oxidation is a total no-no after beer fermentation has started, unlike wine where a small amount of oxygen is sometimes beneficial).

This may seem incredibly basic, but sometimes things slip through the cracks. If you have kegging equipment, you have everything you need to never have problems with racking. For brewers, you can use CO2 to start the siphon as well as blanket the bottom of the vessel that you are siphoning into to prevent aeration. Winemakers will be using either nitrogen or argon more often due to blanketing capabilities as well as a desire to minimize carbonic acid production.

|